Adventures in 3D printing

I've gone in deep on 3D printing in the past few months. Here's the low-down on what I've been making on the 3D printer, along with a brief personal history of 3D printing.

In my first newsletter about getting off the treadmill (aka, quitting my day job), I talked about what I would be up to in my retirement, which included a wide variety of activities from writing and publishing to 3D printing. Many of you have asked me questions about 3D printing, so I figured it would be good to talk about that a little bit. I know this is a bit of a departure from what I’ve been writing about so far, so please leave a comment and let me know if I’ve gone too far off the rails here, haha.

My 3D printing journey

First, my history with 3D printing actually goes back to 2006! My college was able to get a grant from the National Science Foundation to get a 3D printer, we got a zCorp ZPrinter® 310 Plus that used powder and resin method for printing. It cost around $30k. It was the size of a large industrial copy machine. It took all night to print one small 4” cube model. It produced models that were so delicate you had to handle them with gloves.

I got introduced to 3D printing in my CSC240 - COMPUTER GRAPHICS course at Smith College with Professor Joe O'Rourke (are you impressed yet with my use of the WayBack Machine?). I was able to track down an article about my work with the 3D printer that was published in the Winter of 2007 and – ahem – hasn’t aged too well. Behold this hilarious paragraph:

It seems like Dines, who opened her own e-mail account when she was only 7 years old, is always online. She may be somewhat atypical as she spends hours in front of her dual-core Intel processor computer every day—for class updates and course work, a work-study job with Smith’s Information Technology Services, a burgeoning consulting business as a Web designer and, perhaps most absorbingly, for socializing. She has downloaded Google Earth “just to play around with.” One of her biggest concerns is that there are not enough campus locations for free wireless access to the Internet. She’d like to be able trek around campus with her laptop and still stay connected without constantly searching for wireless hot spots.

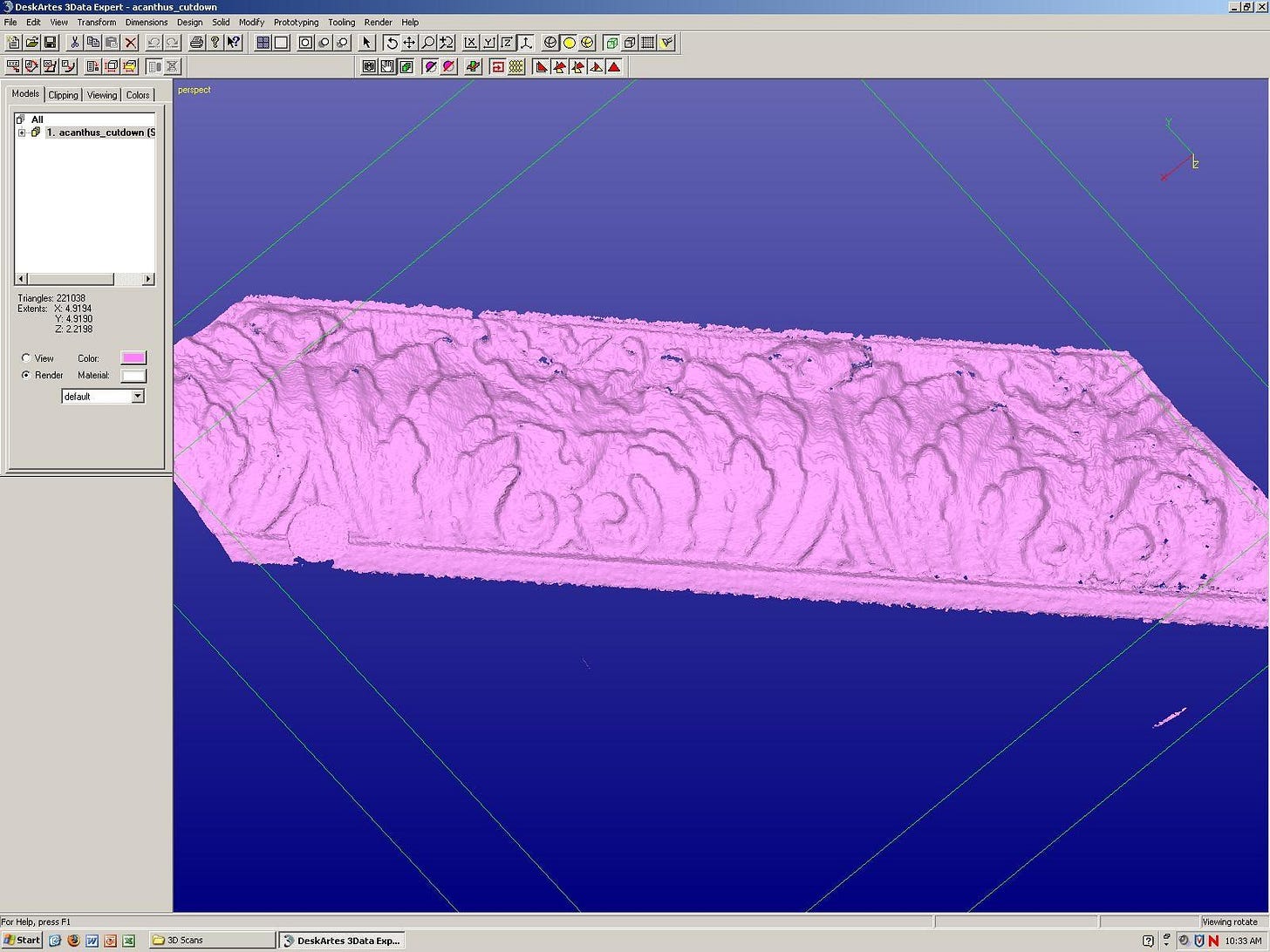

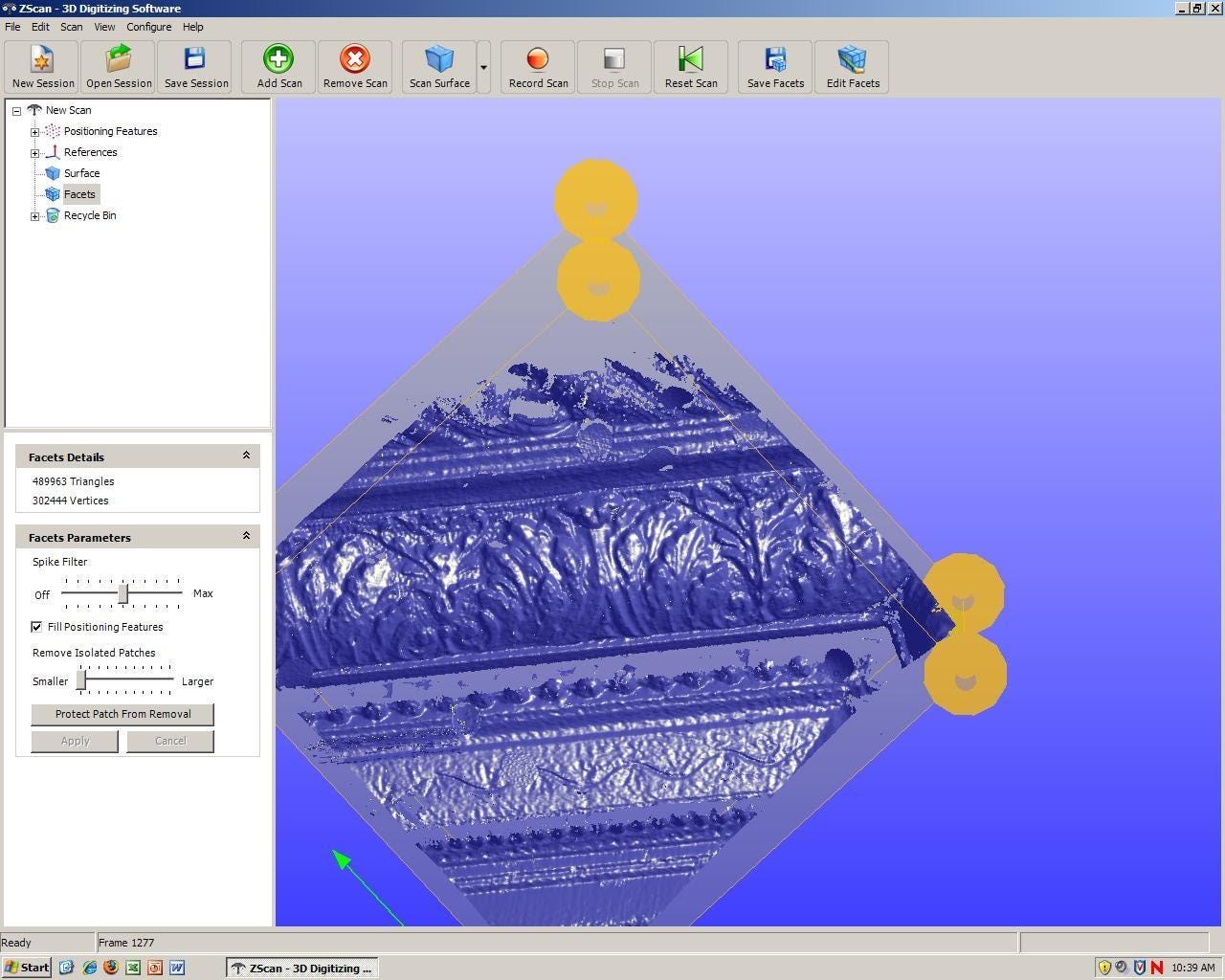

My goodness, I was a brat. I wanted Wifi hotspots everywhere? Also, the little brag about my DUAL-core Intel processor? NERD. All of this led to me doing a special senior project on 3D printing and scanning and its application in the art world! Yup, I’m a double threat, I was studying both Art History and Computer Science. I found the archive of my website explaining the project, but without the pictures, it’s a bit hard to follow, so I’ll include the pictures I can find here:

I’m still trying to track down a picture of me holding the giant 3D scanner (wearing a wrist brace, BTW because the thing gave me carpal tunnel) and scanning artwork in the museum. I know the picture exists and used to live on my website, but I can’t find it anywhere.

Anyhow, fast forward to the end of my senior year of college, it’s 2007, I’m pretty good with 3D printers and scanners and I think “hey, I can find a career in this, right?” WRONG. Oh so wrong. It’s ok though, I ended up getting recruited into Forrester Research, became an industry analyst, got to work on cloud in the days when Amazon was still just a bookseller, from there moved into product marketing, and the rest is, well, my career history. So I’m not mad about it.

3D Printing today

Enough backstory, where am I today? As I sit here writing this in my office, my 3D printer is humming along making Lego themed Valentines Day cards for my son. I’d been following the 3D printer market and was waiting for the point when they seemed consumer friendly enough to buy one to have at home. Why wait so long? While I do have the ability to do software and hardware troubleshooting, I don’t have the time or the patience. But over the past few years, 3D printers have been making huge strides in usability. The things I was most concerned with were out of the box usability and ongoing maintenance. There’s also been a lot of churn in the 3D printer manufacturers, with some going out of business, others exiting the consumer market, so I wanted to make sure that I was purchasing something that have long-term support. After a ton of research, I decided I wanted the A1 Bambu Mini (which was given to me as a birthday gift from my mother-in-law and grandmother-in-law, two amazing women). BTW, I should mention that there are no affiliate links in here and I have no commercial relationship with Bambu.

3D printing has come a LONG way since my days of using the Zcorp machine. For under $400, you can get an entry-level printer that can do multi-color prints and requires little-to-no technical knowledge. There is a learning curve, but I found the on-ramp pretty quick. Note that I do have a background in this, but my knowledge was over a decade old. What’s amazing is the vast amount of open source 3D models out there on places like Thingiverse, Printables, and MakerWorld (among others). Yes, some people do sell their models, but the majority of designers seem to list their models for free personal use (you must pay if you want to monetize their models, which makes perfect sense to me). As someone who has been in the technocraft (I just came up with this, LOL) community for a long time, this was a welcome surprise. Cricut has long dominated this space, with newer entrants like Glowforge coming in hot (laser joke intended). What’s interesting, though, in the world of Cricut, the majority of people charge for their designs, very few give them away for free. The opposite is true in the world of 3D printing.

So what are we printing?

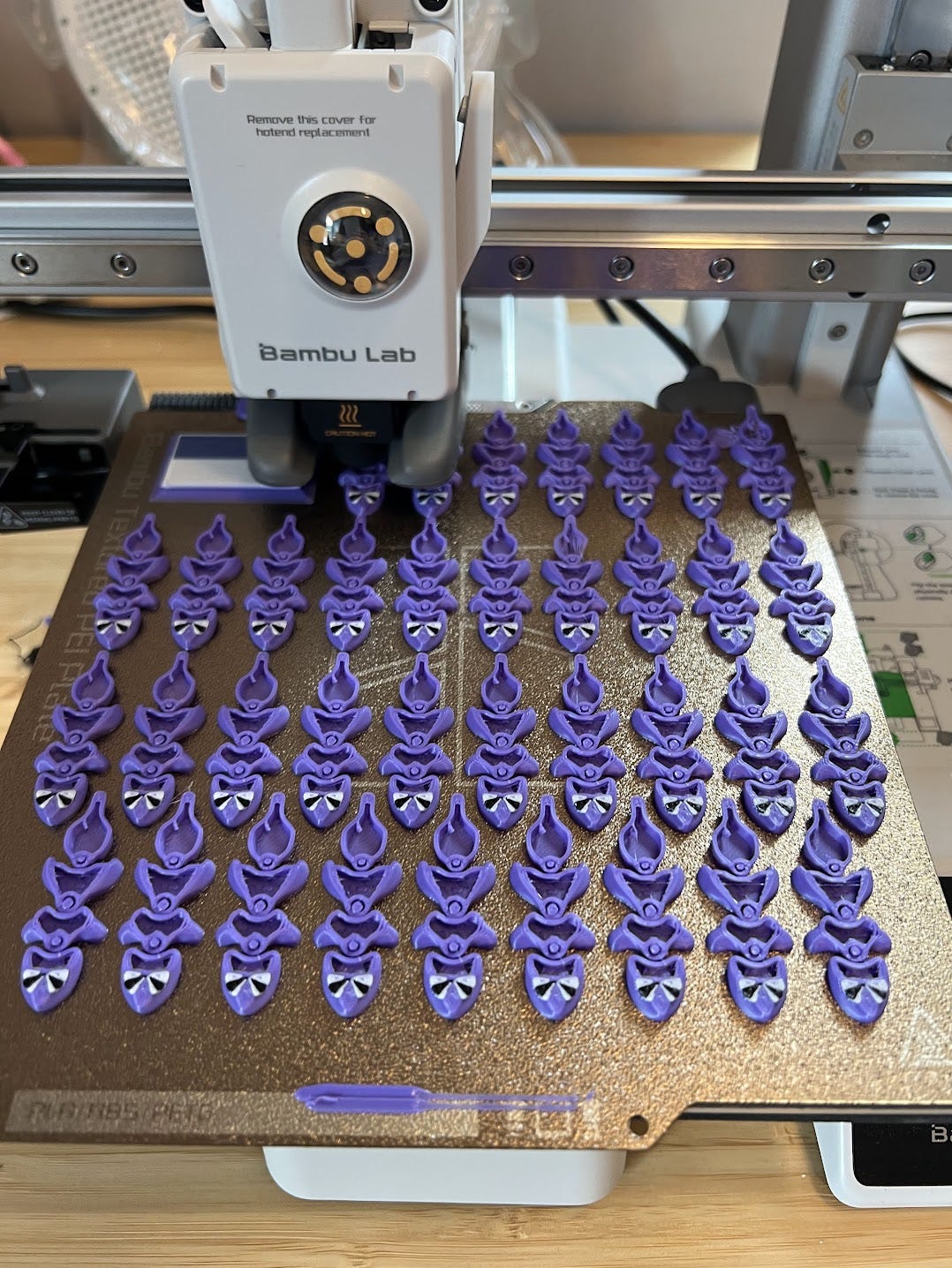

I immediately started designing my own models again, using TinkerCAD and Blender (both free/open source!). My first big project was favors for my son’s 6th birthday party. My son has an imaginary (he would immediately correct me that they are real) creature called a Macky. They are similar to a dinosaur crossed with a dragon, but miniature. He came up with Mackys when he was three years old and they’ve stuck around and multiplied – new species are discovered constantly. So for his party favors, he wanted me to make him Mackys on the 3D printer. I set out to design a creature that looked like what he imagined. We spent many hours together while I modeled and he gave me suggestions on how to make the Macky look more “realistic.” After many tests, failures, and iterations, we landed a design we were fairly happy with. We printed up a few dozen, packed them into plastic vending machine eggs, and gave them to his friends. The kids LOVED them. My son started telling everyone we had a website and I shrugged and said “I guess I’ll build you one.” Mackys are for sale on the site and on Etsy, where I’m offering readers a 25% discount with the code TECHDROPOUT.

Ok, but can you print anything useful?

The printer is not just for designing tchotchkes and kids toys (although I’ll admit that kids toys are a big component of what I print. My son is really into Gravitrax, which is a complicated marble run from Germany, and there is a big community of people making 3D print designs for this toy that are honestly pretty cool.) The other main thing that I print is random stuff for organization and wall mounting. For example, I’m currently on a quest to organize our kitchen, so I designed and printed this tea bag organizer. I am in the process of printing drawer divider organizers and a holder for our bike lights (we use battery powered Christmas lights to add extra visibility to our cargo bike in the dark). I’ve also printed numerous custom wall brackets, for shelves, for mounting hot wheels, for holding coffee filters. And yes, I did make the obligatory Giant Lego Wreath.

Most importantly, it’s been a fun activity for my son and I to create things together. He is too young to really participate in the 3D modeling or the printing itself, but he likes to watch and learn. And he’s definitely learning – if you ask him about filament or infill he will talk your ear off.

What’s next for 3D printing?

3D printing at home feels like it's crossing the chasm – making the leap from early adopters to early majority. I’m hopeful that the state of the technology manufacturers, which has been a bit bumpy for the past few years, is starting to smooth out. I’m surprised none of the major consumer technology or technocraft brands have jumped into this space yet. I wouldn’t be surprised if folks like Cricut or Brother joined in this space via acquisition or in-house innovation. It’s changed our mindset on buying things from “let’s go to Amazon” to “how much would it cost to 3D print that?” Not all plastic things make more sense to 3D print than to buy, but so far I’ve found that most things are less expensive to print at home.

That’s all for now! I hope I answered most of your questions about 3D printing, reach out if you want to talk about it more, I clearly love to nerd out on this topic.